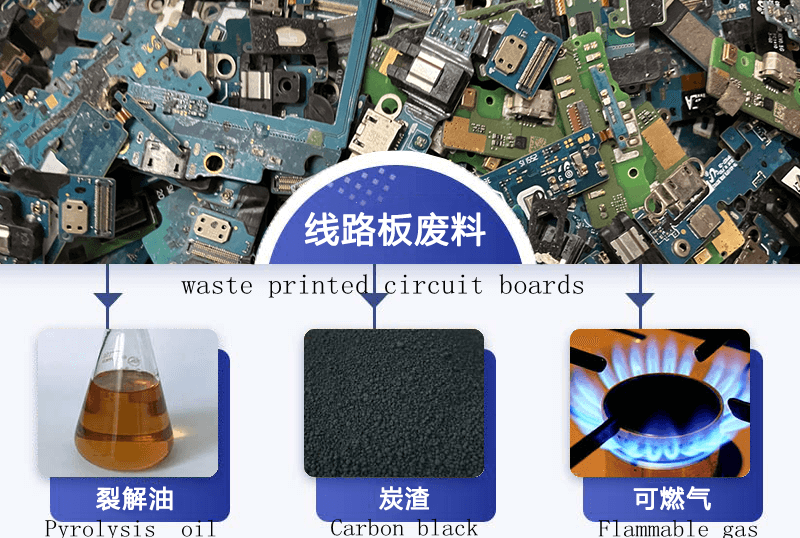

The essence of pyrolysis is to heat waste PCB printed circuit boards in different ways to reach the thermal decomposition temperature of organic substances and undergo thermal decomposition reactions, thereby obtaining solid residues, pyrolysis oil, and pyrolysis gas products. It is the ultimate way to dispose and recycle waste PCB printed circuit boards.

Pyrolysis, also known as dry distillation in industry, is a process of heating waste PCB in an oxygen-free or anoxic environment, utilizing the thermal instability of organic matter to cause the organic matter therein to undergo a thermal cracking process and decompose into small molecular substances, resulting in various pyrolysis gases, pyrolysis oils, and solid residues. Pyrolysis reaction process is a complex and diverse process that involves a series of physical transformations and chemical reactions. It can be summarized as the following five components: the heat transfer of external heat and the temperature rise inside the discarded PCB; As the temperature inside the PCB continues to rise, the pyrolysis reaction of low molecular organic compounds inside the PCB begins, producing volatile components; Volatile components generated by pyrolysis are continuously generated and transferred outwards, and heat transfer occurs between high-temperature volatile components and low-temperature non pyrolysis PCBs; The temperature of the volatile matter that can be condensed decreases and is condensed into pyrolysis tar; The secondary reaction between coke in pyrolysis residue, organic matter in PCB, and pyrolysis tar. The pyrolysis reaction process of organic compounds can be simply represented by the following general formula:

Organic matter - G (gas)+L (liquid)+S (solid)

The product of pyrolysis reaction mainly consists of the following three parts: flammable gases such as hydrocarbons, carbon monoxide, and hydrogen; Liquid mixtures of organic substances such as tar, methanol, brominated hydrocarbons, etc; Solid residues such as coke, glass fibers, and metals. The composition and yield of the above reaction products vary depending on factors such as the type of raw material, heating speed, heating temperature, residence time, and reactor type. Under low temperature heating conditions, the small molecular organic compounds produced by pyrolysis have sufficient time to recombine and undergo secondary reactions to generate larger components of liquids or solids. Under high temperature heating, the organic matter fully absorbs heat and undergoes intense and sufficient thermal decomposition, resulting in a large amount of low molecular weight organic matter, resulting in a large gas component and yield in the product.

Due to the fact that the pyrolysis process is conducted in a closed atmosphere without oxygen or oxygen deficiency, it can effectively suppress the toxic and harmful substances produced by combustion in an oxygen environment. At the same time, the reductive coke present in the pyrolysis solid residue can effectively inhibit the formation of metal oxides and toxic and harmful substances, which is conducive to reducing secondary pollution to the ecological environment.

next:No more