On the afternoon of February 11th, two sets of LES-2675 pyrolysis plant designed and manufactured by the professional manufacturer of solid waste pyrolysis equipment, Lefeierte Shangqiu Branch, were loaded and shipped to Hubei. Our technical engineer accompanied the vehicle and have arrived at the project site in Hubei at noon yesterday. The equipment installation work is currently underway. We will also continue to monitor the progress of the project and look forward to the early and smooth production of this project, Make due contributions to the recycling and utilization of circuit board waste in Hubei.

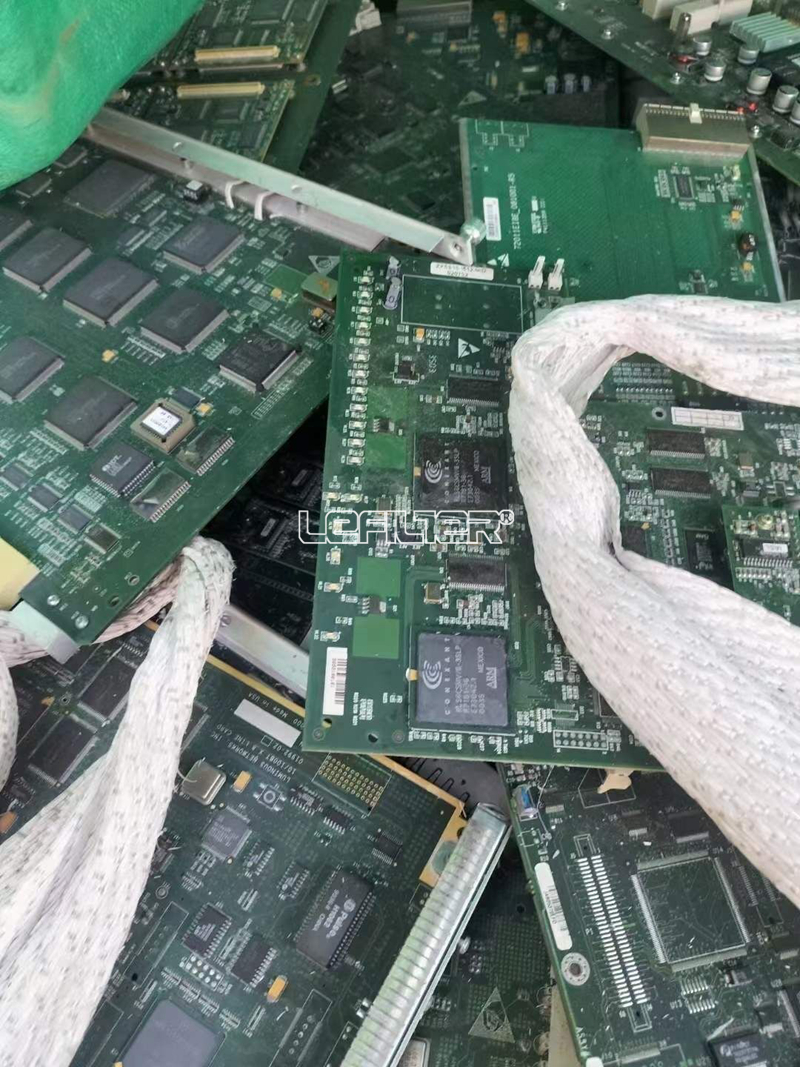

These two sets pyrolysis equipment were ordered in October,2022 and are mainly used for the resource utilization of circuit board waste disassembled from household appliances and refrigerators. The daily processing capacity of the first phase of the project is 10 tons, which is produced intermittently.

After the temperature rises to a certain degree, the organic substances in the circuit board waste are pyrolysed to generate pyrolysis oil, while metals and other impurities are left in the pyrolysis residue.

As the pyrolysis process is conducted in a closed atmosphere without oxygen or oxygen deficiency, Therefore, it can effectively inhibit the formation of toxic and harmful substances generated by combustion in an oxygen environment, and the presence of reducing coke in the pyrolysis solid residue can effectively inhibit the formation of metal oxides and toxic and harmful substances, which is conducive to reducing secondary pollution to the ecological environment.