What kind of plastics can be pyrolysised to oil ?

What kind of plastics can be pyrolysised to oil ?

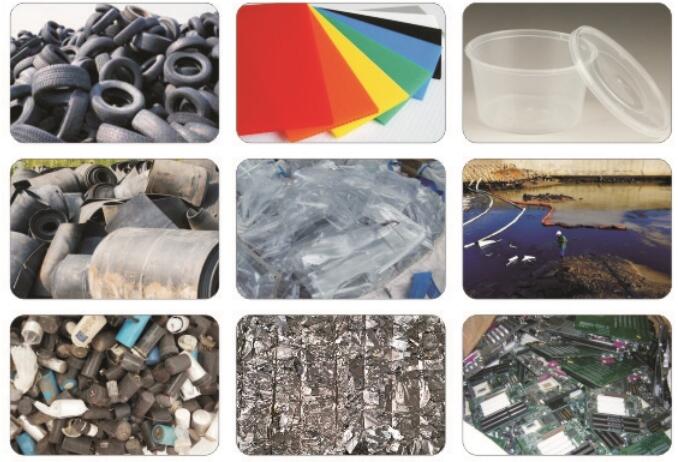

Waste plastic can be processed to fuel oil by pyrolysis plant. What kind of plastic can make fuel oil ?

Different plastics have different characteristics of pyrolysis reaction. Generally, the larger the substituent group of the branch chain, the easier the decomposition reaction.

The thermal cracking of polyethylene (PE) is characterized by many solid waxes, and the lighter part is mainly n-alkanes. From the perspective of material balance, the catalytic reaction results show that the liquid yield is not high, the coking is serious, and the products contain a large amount of solid waxes, indicating that there are many straight chain alkanes or long branched chain hydrocarbons. From the above analysis, it can be seen that by comparing thermal cracking to wax and catalytic cracking to gasoline and diesel, ethylene polymer catalytic cracking to produce high-quality gasoline requires further screening of catalysts or other measures, and wax production is relatively more effective.

The main product of thermal cracking of polypropylene (PP) is a mixture of solid and liquid, which is slightly yellow in color. Compared with the thermal cracking of ethylene polymers, there are fewer solid products and more liquid products. The main products of catalytic reaction are transparent and yellowish liquid.

The liquid yield of polystyrene (PS) pyrolysis is higher than that of other polymers. The products are mainly styrene monomer, dimer and trimer of styrene monomer. PS pyrolysis reaction is mainly in the form of open chain, which tends to generate monomer styrene and polymer with few structural units. These substances are liquid at room temperature, so PS pyrolysis products are basically liquid at room temperature. The liquid yield of Ps catalytic reaction is lower than that of mature pyrolysis, and coking is serious. From the composition of PS catalytic reaction and pyrolysis reaction products, PS can be directly pyrolyzed to obtain styrene monomer with high utilization value, which is very promising in industry. Monocyclic aromatic hydrocarbons such as ethylbenzene can be obtained by catalytic reaction, which can be separated into chemical products, and can also be used as high octane blending components of gasoline.

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com