Application prospect of waste tire pyrolysis oil

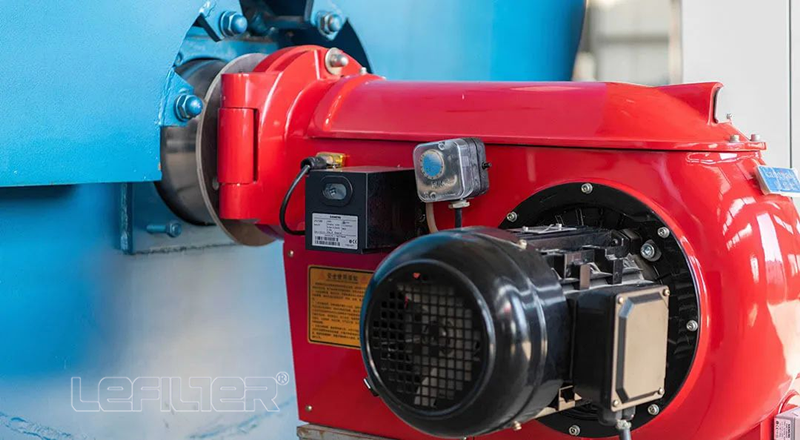

01 Pyrolysis oil as fuel oil

The heat value of tire pyrolysis oil is generally greater than 40MJ/kg, which can be burned as a whole. Compared with heavy diesel oil, except for the low specific gravity of diesel oil at flash point, other conditions of de oiling meet the standard of heavy diesel oil. It can be used as a conventional liquid fuel for industrial boilers and power station boilers, and can also be mixed with heavy diesel oil by taking advantage of the low viscosity of pyrolysis oil, so as to improve the overall atomization effect. Burning pyrolysis oil instead of some petroleum crude oil as fuel can alleviate the shortage of petroleum resources to a certain extent.

Although it is easy to directly use the pyrolysis oil of tires as fuel, the economic benefits are not high. As the pyrolysis oil belongs to the oil with wide boiling point, it can be used as light fraction (<200 ℃), medium fraction (200~350 ℃) and heavy fraction (>350 ℃) after distillation under the condition of large processing scale.

02 Application Scheme of Light Distillate

For light pyrolysis oil (fraction with boiling point<200 ℃), further distill and cut it, and compare the naphtha fraction with boiling point<160 ℃ and petroleum naphtha (fraction with boiling point<152 ℃). Pyrolysis naphtha is dominated by olefins and aromatics, while petroleum naphtha is dominated by saturated alkanes. Therefore, pyrolysis naphtha can not directly produce gasoline, but can fully utilize the high proportion of naphtha and high aromatic hydrocarbon content in pyrolysis naphtha to extract chemical raw materials.

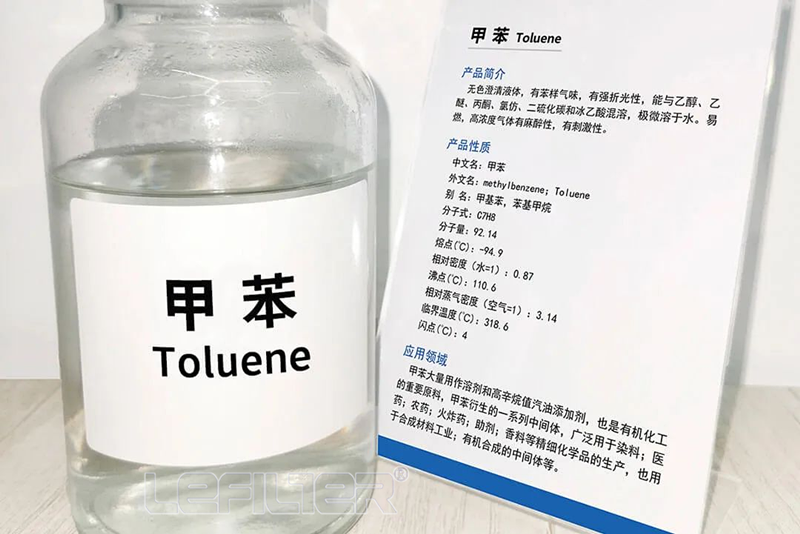

A .Extract BTX and styrene

Naphtha contains quite high content of light monocyclic aromatic hydrocarbons BTX (benzene, toluene, xylene) and other substances. BTX has high industrial application value. It can be produced by secondary aromatization reaction at high pyrolysis temperature. The highest content of single substance in pyrolysis oil was 36.4wt.% benzene, 16.8wt.% toluene, 3.95wt.% xylene and 5.83wt.% styrene, respectively. Therefore, extracting high content BTX is one of the utilization schemes of light fraction pyrolysis oil.

B.Separation of limonene

Limonene, which is a kind of environment-friendly solvent and aromatic agent with high content in light fraction pyrolysis oil, is widely used in industry. The limonene content was 3.1 wt.% and 2.5 wt.% at 450 ℃ and 600 ℃, respectively. Therefore, separation of limonene by effective methods is also one of the utilization ways of light fraction pyrolysis oil.

03 Application Scheme of Medium and Above Distillates

The middle distillate of pyrolysis oil has high acidity, low aniline point, low freezing point, and high sulfur and nitrogen content. It needs to be refined by desulfurization, denitrification, deacidification and hydrogenation, and can be used as diesel oil.

Compared with the operating oil Sundex790 used in rubber production, the pyrolysis oil (>204 ℃) above the middle grade has good mechanical properties and lubricating properties similar to industrial aromatic oil, although there are some differences in chemical composition between them. The vulcanization process of rubber is accelerated after adding the pyrolysis oil, so the corresponding components in the pyrolysis oil above the middle grade can be used as rubber operating oil and industrial aromatic oil.

04 Heavy fraction application scheme

On the one hand, it can be used as the binder and modifier of paving asphalt, or mixed with low penetration petroleum asphalt. In addition, the fraction of pyrolysis oil>400 ℃ has low aromaticity, but shows moderate permeability, high softening point and low viscosity, and its rheological properties are similar to those of petroleum asphalt. If the pyrolysis oil asphalt is added to the petroleum asphalt, the thermal stability of the asphalt at medium and high temperatures can be significantly improved, thus it is not easy to age.

On the other hand, using the heavy oil utilization plan of petroleum industry for reference, the heavy distillate can be delayed coked to produce high-quality coke and heavy diesel oil. The heavy pyrolysis oil meets all the indexes for producing high-quality coke raw materials. One ton of waste tire can get 28kg of pyrolytic oil coke, and high quality by-products can also be recovered, including high calorific value gas, highly aromatic naphtha, light diesel oil and heavy diesel oil that can be directly recycled in the coking system.

Lefilter Shangqiu Branch adheres to the tenet of "making customers more satisfied when using than when purchasing". Every customer's satisfaction with the use of Lefilter products will bring us a great sense of achievement. Our goal is to provide customers with high-quality products at competitive prices. Looking forward to the future, the company will continue to develop steadily, form an industrial pattern with large-scale development, specialized operation, regional business and differentiated management, adhere to the path of cracking equipment specialization, and strive to become a leading supplier of solid waste cracking solutions in globe.

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com