Lefilter successful cases for semi-continuous rubber powder pyrolysis plant in Brazil.

Lefilter successful cases for semi-continuous rubber powder pyrolysis plant in Brazil.

progrecess for semi-continuous pyrolysis plant

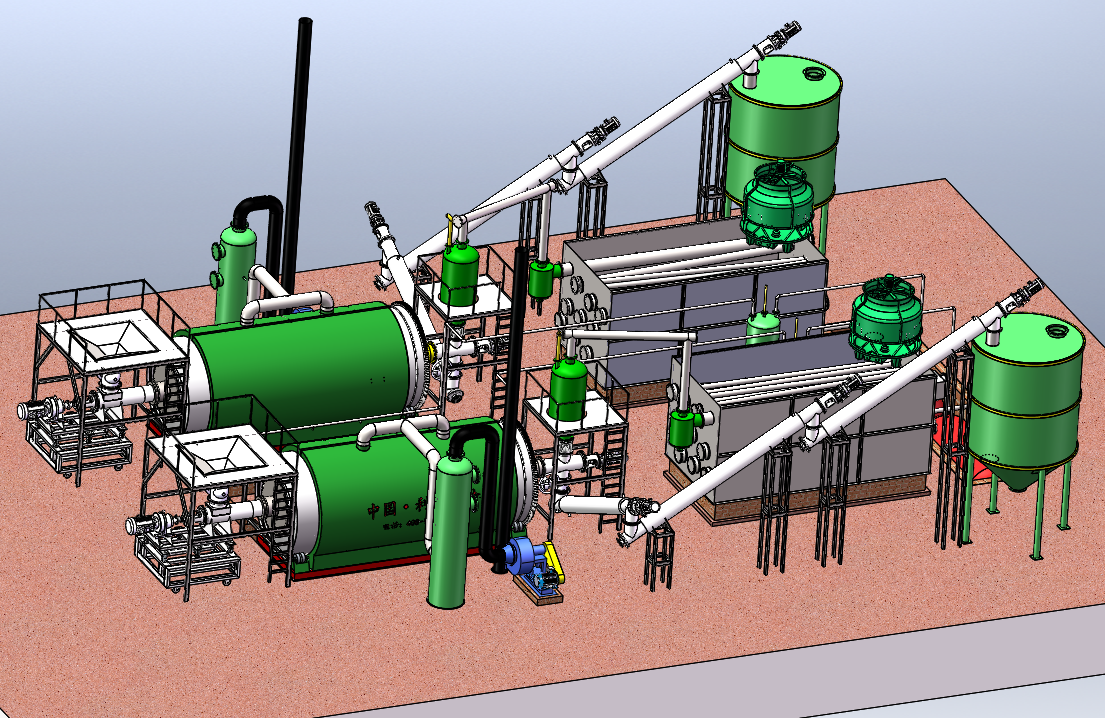

Feeding :

The rubber powder is fed into the pyrolysis reactor with a fully automatic feeding screw conveyor, and the high-temperature ball valve is closed to make it pyrolysis in a closed and oxygen free environment, without opening the furnace door in the whole process.

Heating:

Use fuel oil to heat the pyrolysis reactor, and the temperature will slowly rise in the reactor. When the temperature in the reactor reaches about 150 ℃, the oil and gas will start to generate.Then heat by flammable gas .

Cooling:

The oil gas generated after heating passes through the condensing device, and is cooled into tire oil and stored in the oil storage tank. The oil gas that cannot be cooled is recycled to the reactor of waste tire treatment equipment as the main fuel heating furnace, which can greatly save fuel oil.

Discharging:

After the tire powder is completely pyrolysised, the carbon black in the reactor can be transported to the carbon black rotary reactor through the water-cooled auger under high temperature. The carbon black will naturally cool to about 80 ℃ in the rotary reactor and will be collected and stored in jumbo bags.

Technical Parameter:

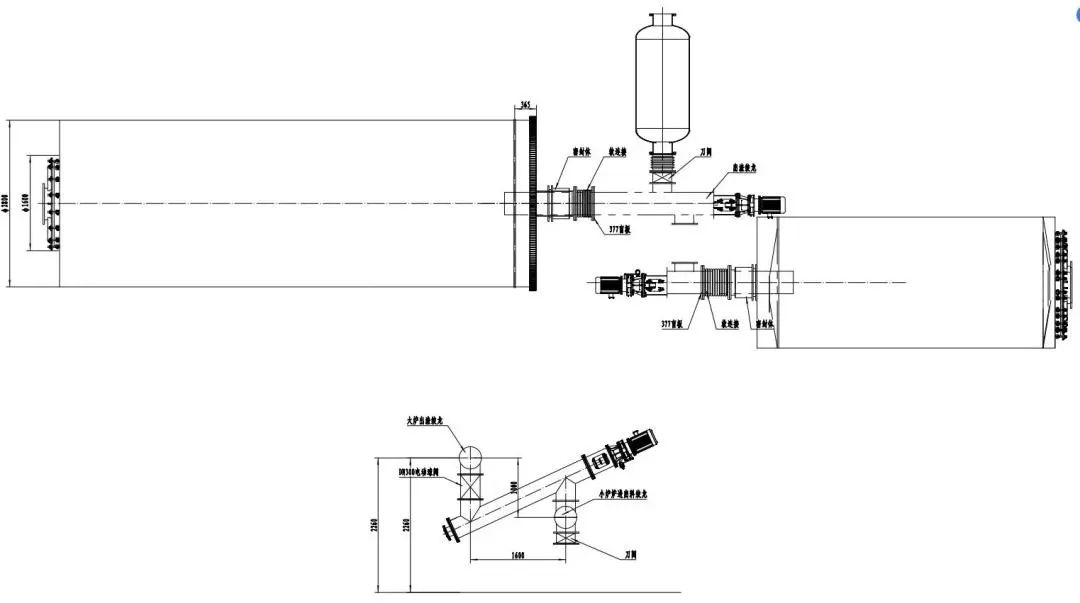

[Equipment model] LES-2880

[Main furnace size] ∅ 2800 × eight thousand

[Structure] Horizontal rotation

[Feeding mode] Automatic feeding

[Working pressure] Normal pressure

[Main furnace speed] 0.4 rpm

[Installed power] 10kw-12kw

【Transmission mode】 Gear transmission

Lefilter semi continuous pyrolysis plant is mainly used for processing small granular raw materials after crushing, such as rubber powder, rubber granules,rubber crumb and shred plastic. The equipment can realize high temperature discharging. The production cycle is greatly shortened, and the treatment effect is more thorough, and the oil yield can reach 50%.It includes feeding platform, pyrolysis plant , oil gas separator , condensate tank, , oil storage tank, carbon black rotary furnace, etc.

Shipment

Mobile/Wechat/Whatsapp:+86-13523737997

Mobile/Wechat/Whatsapp:+86-13523737997

Email:recycling@lefilter.com

Email:recycling@lefilter.com